Image 1 of 1

Image 1 of 1

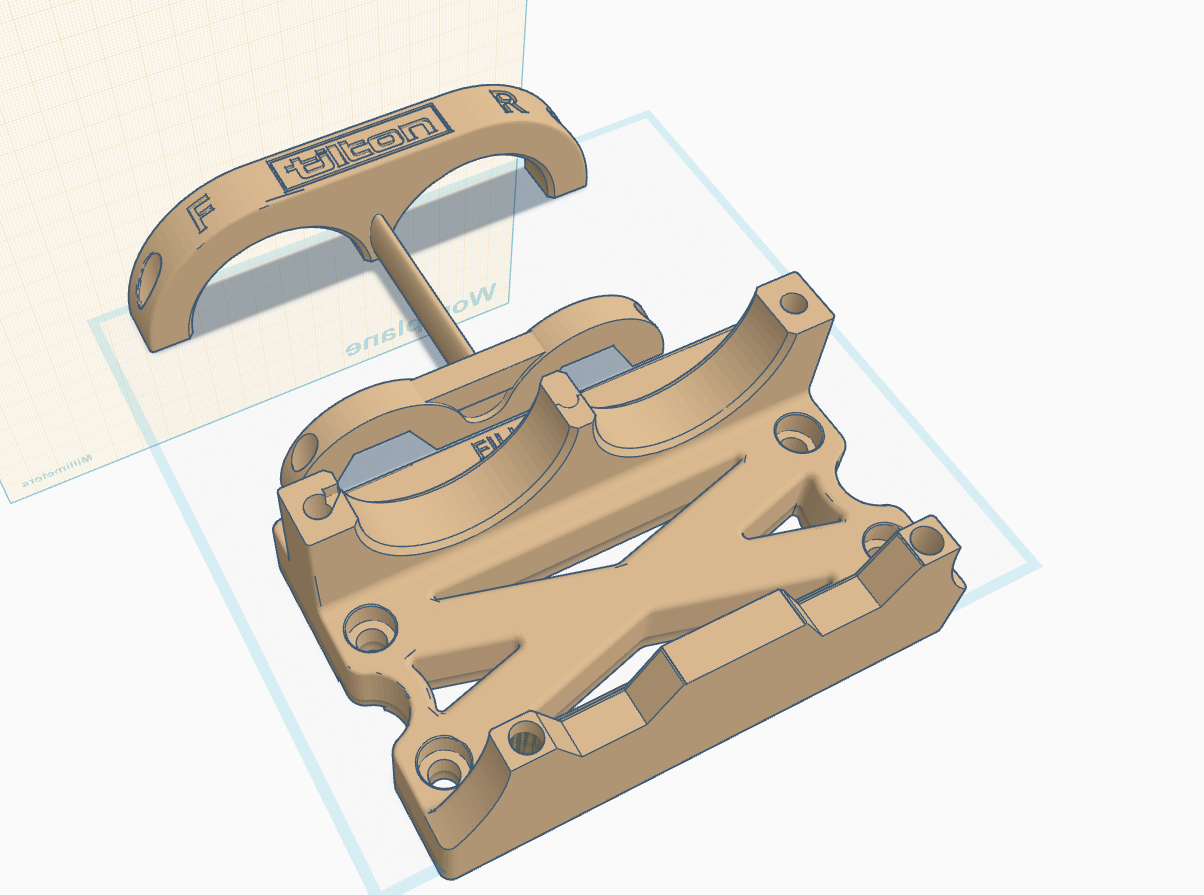

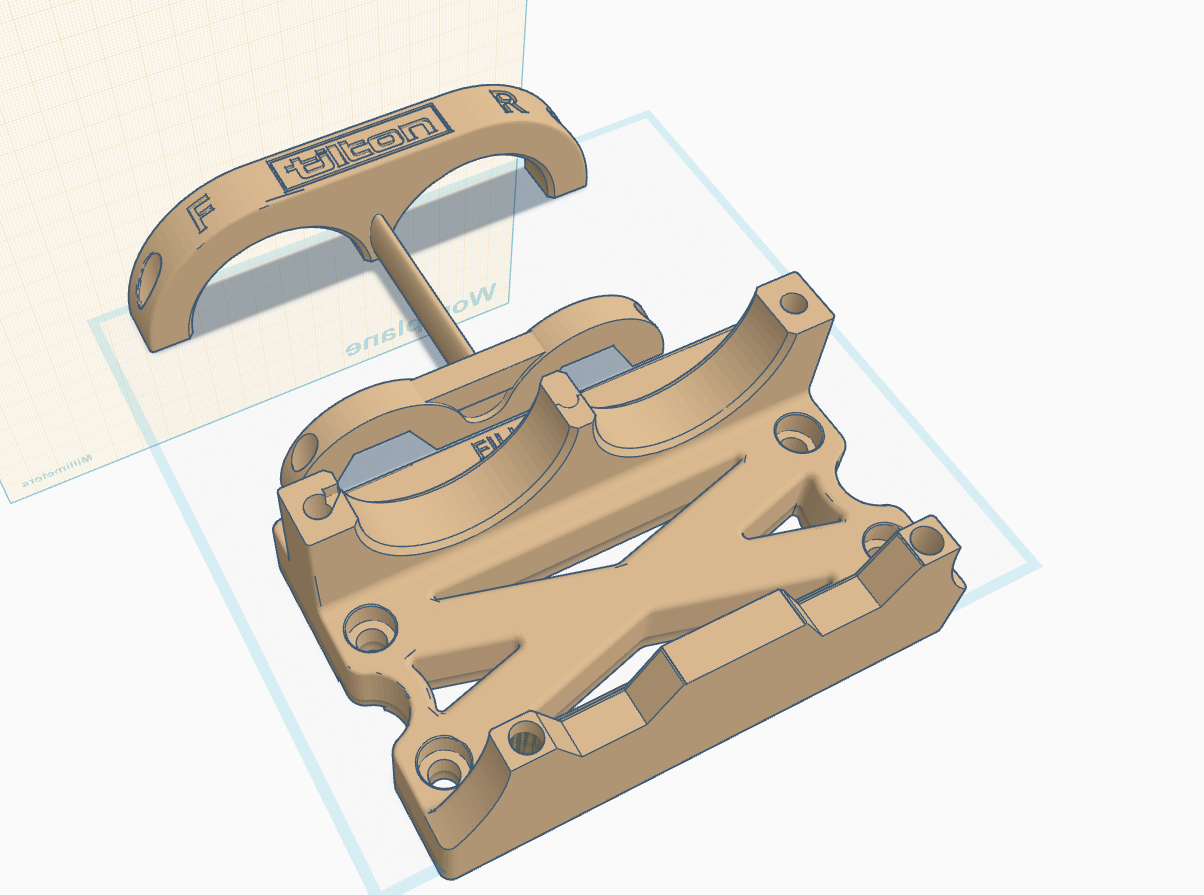

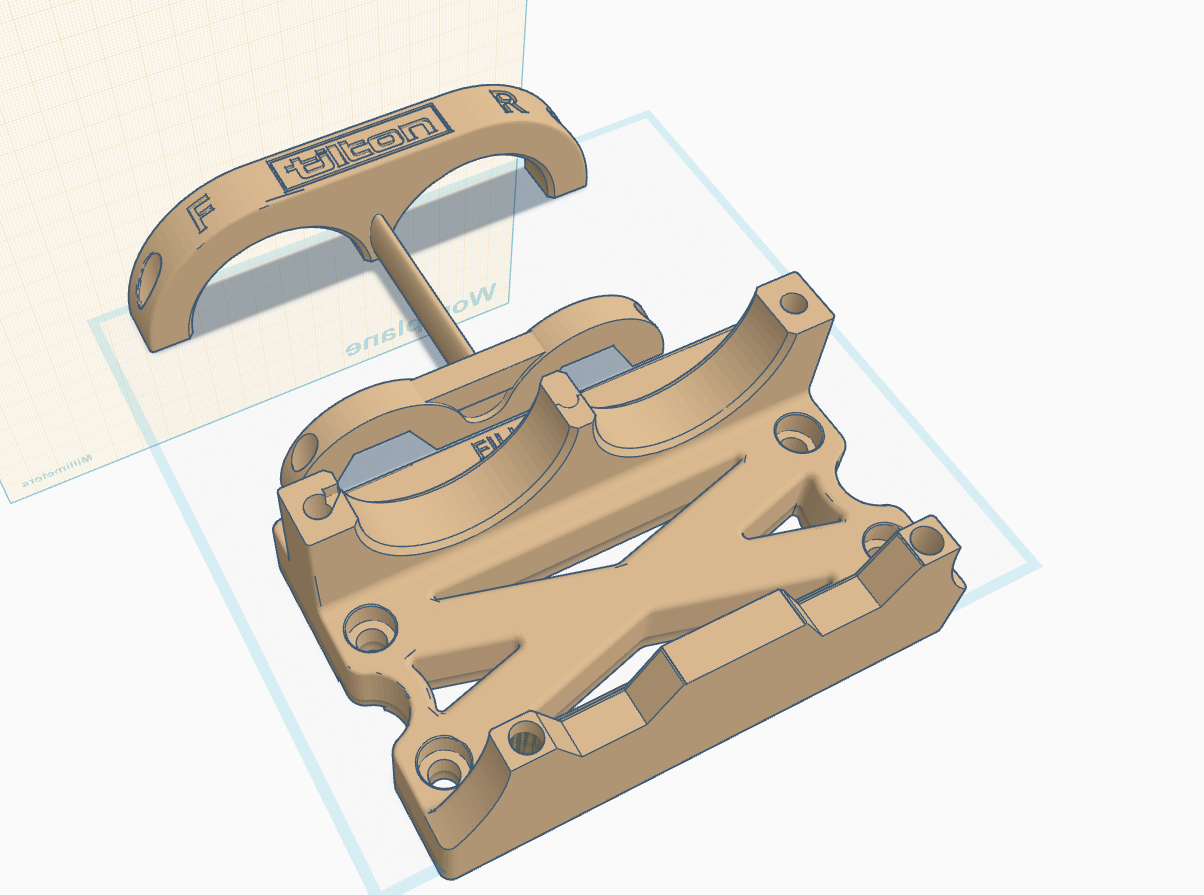

Project Limit Break Tilton Brake Master Cylinder Reservoir Bracket

Tilton 74-230 Series Master Cylinder Reservoir Bracket — PETG-CF Composite

Description:

This precision 3D-printed bracket is designed to securely mount Tilton 74-230 series remote master cylinder reservoirs, as well as other models with similar dimensions, including Tilton 74-231 and Wilwood 260-11097.

Constructed from carbon-fiber-reinforced PETG (PETG-CF), it provides an exceptional balance of strength, light weight, and vibration resistance, making it ideal for performance and motorsport applications where reliability and precision are essential.

Material & Construction:

Printed in PETG-CF composite for high rigidity and dimensional stability

Includes four M4 socket cap bolts for securing the two bracket halves together

Designed with bolt-through reinforcement points for long-term durability under vibration

Features a clean, matte carbon finish with a functional, purposeful surface texture

Fitment:

Compatible with Tilton 74-230 Series remote reservoirs (60 ml, 75 ml, and 120 ml sizes)

Also suitable for:

Tilton 74-231 (single outlet, similar bolt spacing)

Wilwood 260-11097 remote reservoir (with light modification)

Generic round reservoirs between 44 mm and 47 mm base diameter

Installation Notes:

For best results, mount the assembled bracket using rubber isolators to reduce vibration and stress.

Do not use impact tools or overtighten hardware; excessive torque may damage the printed structure or crush mounting surfaces.

Intended for cockpit, firewall, or chassis-mounted locations; not recommended for engine bay use.

For an engine-bay-capable version, please contact us for the ASA-CF high-temperature model (not yet listed).

Maintenance & Care:

Resistant to incidental brake-fluid exposure, but not designed for long-term immersion.

In the event of fluid contact:

Wipe immediately with a soft cloth or paper towel.

Clean with isopropyl alcohol (IPA) or a mild automotive degreaser.

Avoid acetone or strong solvents.

Rinse lightly with water and dry thoroughly.

Regular cleaning preserves surface quality and mechanical integrity.

Recommended Environment:

Interior, firewall, or protected chassis mounting.

Not for direct engine bay exposure (use ASA-CF variant).

Tilton 74-230 Series Master Cylinder Reservoir Bracket — PETG-CF Composite

Description:

This precision 3D-printed bracket is designed to securely mount Tilton 74-230 series remote master cylinder reservoirs, as well as other models with similar dimensions, including Tilton 74-231 and Wilwood 260-11097.

Constructed from carbon-fiber-reinforced PETG (PETG-CF), it provides an exceptional balance of strength, light weight, and vibration resistance, making it ideal for performance and motorsport applications where reliability and precision are essential.

Material & Construction:

Printed in PETG-CF composite for high rigidity and dimensional stability

Includes four M4 socket cap bolts for securing the two bracket halves together

Designed with bolt-through reinforcement points for long-term durability under vibration

Features a clean, matte carbon finish with a functional, purposeful surface texture

Fitment:

Compatible with Tilton 74-230 Series remote reservoirs (60 ml, 75 ml, and 120 ml sizes)

Also suitable for:

Tilton 74-231 (single outlet, similar bolt spacing)

Wilwood 260-11097 remote reservoir (with light modification)

Generic round reservoirs between 44 mm and 47 mm base diameter

Installation Notes:

For best results, mount the assembled bracket using rubber isolators to reduce vibration and stress.

Do not use impact tools or overtighten hardware; excessive torque may damage the printed structure or crush mounting surfaces.

Intended for cockpit, firewall, or chassis-mounted locations; not recommended for engine bay use.

For an engine-bay-capable version, please contact us for the ASA-CF high-temperature model (not yet listed).

Maintenance & Care:

Resistant to incidental brake-fluid exposure, but not designed for long-term immersion.

In the event of fluid contact:

Wipe immediately with a soft cloth or paper towel.

Clean with isopropyl alcohol (IPA) or a mild automotive degreaser.

Avoid acetone or strong solvents.

Rinse lightly with water and dry thoroughly.

Regular cleaning preserves surface quality and mechanical integrity.

Recommended Environment:

Interior, firewall, or protected chassis mounting.

Not for direct engine bay exposure (use ASA-CF variant).